What is a Ball Screw for Sale and How to Choose One?

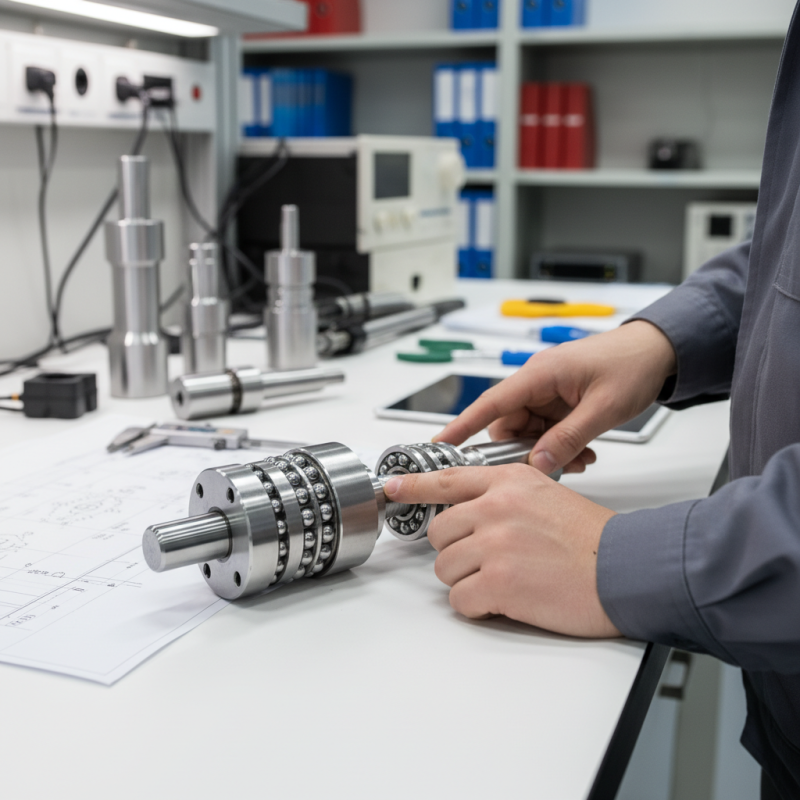

In the world of precision engineering, a ball screw is a vital component. It converts rotational motion into linear motion with remarkable efficiency. Michael Anderson, a renowned expert in linear motion systems, emphasizes, “Selecting the right ball screw is crucial for optimal machine performance.” For those browsing the market, finding the ideal "ball screw for sale" requires careful consideration.

When choosing a ball screw, factors such as load capacity, accuracy, and environmental conditions play a key role. Many buyers overlook these aspects, leading to subpar performance. The size, lead, and materials used in the ball screw can influence both longevity and functionality. It's not just about getting a good price; it’s about finding a product that meets specific machinery needs.

Challenges often arise when making choices. Many options can confuse and overwhelm potential buyers. Furthermore, industry standards frequently change, adding to the complexity. To navigate this landscape, it's important to seek expert advice. Ultimately, selecting the right ball screw for sale can significantly affect overall project success.

What is a Ball Screw and Its Function in Machinery?

A ball screw is a mechanical device widely used in machinery. It converts rotary motion into linear motion. This is achieved through the use of ball bearings that roll between the screw and the nut. This design reduces friction, allowing for smoother and more efficient operation. In fact, studies show that ball screws can achieve up to 90% efficiency in converting motion.

In industries, ball screws play a crucial role. They are often utilized in CNC machines, robotics, and material handling equipment. Research indicates that these devices can improve performance by reducing wear and tear. Notably, their precision contributes to better product quality. Yet, choosing the right ball screw is not always straightforward. Factors such as load capacity, diameter, and lead must be considered. Many users overlook these details, leading to suboptimal performance.

Proper maintenance is essential for longevity. Contamination can lead to failure, which can be costly. Industry reports reveal that many malfunctions stem from neglecting regular inspections. In essence, understanding the function of a ball screw is vital. This knowledge ensures that machinery operates efficiently and reliably.

Key Components of a Ball Screw and Their Roles

Ball screws are essential components in precise motion control systems. They convert rotary motion into linear motion with minimal friction. Each ball screw consists of several key components that contribute to its performance.

The screw shaft is the core element. It features a threaded design that allows ball bearings to move between grooves. These bearings reduce friction and enable smooth movement. A nut surrounds the screw shaft and houses the ball bearings. Proper alignment is crucial here. Misalignment can lead to uneven wear.

Tips: Regularly inspect your ball screw for wear signs. This helps maintain optimal performance.

End supports are the next component. They stabilize the screw shaft and minimize deflection, which occurs during high loads. Accurate installation of these supports is vital. An improper setup can cause vibrations, affecting the system’s accuracy.

Tips: Ensure that the end supports are tightly fixed to avoid misalignment.

Lastly, lubrication cannot be overlooked. It plays a critical role in reducing friction between moving parts. Insufficient lubrication can lead to premature failure. However, over-lubrication can attract dirt, counteracting the benefits.

Tips: Choose the right lubricant for your application. Always follow the manufacturer's recommendations, even if they seem excessive.

What is a Ball Screw for Sale and How to Choose One? - Key Components of a Ball Screw and Their Roles

| Component | Function | Material | Common Sizes (mm) |

|---|---|---|---|

| Screw Shaft | Converts rotary motion into linear motion | Steel | 16, 20, 25 |

| Ball Nut | Contains the return mechanism for the balls | Aluminum Alloy | 16, 20, 25 |

| Ball Bearings | Reduces friction and allows smooth movement | Chrome Steel | 7, 10, 12 |

| End Cap | Holds the balls in the system | Plastic | Varies with design |

| Support Bearing | Provides stability to the assembly | Steel | 5, 10, 15 |

Factors to Consider When Choosing a Ball Screw for Your Project

When choosing a ball screw for your project, several factors come into play. The load capacity is crucial; typically, it should exceed the expected load by 20% to ensure reliability. For high-speed applications, look for screws with a low friction coefficient. According to industry reports, optimal design can improve efficiency by up to 30%. If your project involves automation, consider the screw's diameter and lead. Larger diameters offer greater stiffness, while longer leads can enhance linear movement speed.

Temperature also matters. Ball screws can be sensitive to heat. Operating beyond the recommended temperature range can lead to failure. A good practice is to evaluate the thermoplastic materials used in your ball screw's construction. Many reports suggest a maximum operational temperature of 80 degrees Celsius.

Tips: Always review your application needs before purchasing. Standard specifications might not meet your requirements. Testing in real-world conditions is advisable to catch potential issues. Regular maintenance, such as lubrication every few months, can extend the service life. Remember that each project is unique, and there’s no one-size-fits-all solution. Your choices should align closely with your specific application.

Different Applications of Ball Screws in Industries

Ball screws play a crucial role across various industries. Their precision and efficiency make them ideal for applications requiring linear motion. In automation and robotics, ball screws convert rotary motion into linear motion, enabling accurate positioning. They are vital in CNC machines, where they guide cutting tools with high precision. The ability to minimize friction allows for smoother operation.

In the automotive sector, ball screws are used in electric steering systems. They help achieve a more responsive steering feel. However, if improperly chosen, they can lead to inefficiencies. For example, selecting the wrong size can result in wear or overheating. Meanwhile, in the medical field, ball screws facilitate the operation of surgical robots. They ensure high precision, which is essential during procedures.

Despite their reliability, ball screws require careful consideration when selecting. Factors such as load capacity and speed must match the application’s needs. Overlooking these details can cause costly setbacks. Understanding these dynamics leads to better choices, ultimately enhancing machinery performance.

Comparative Advantages of Ball Screws over Other Lead Screw Types

Ball screws offer several advantages over traditional lead screws. Their design incorporates ball bearings that reduce friction. This results in smoother and more efficient motion. With lower friction, ball screws can handle higher loads while generating less heat. This efficiency is ideal for applications requiring precision and speed.

Additionally, ball screws have a higher lead accuracy compared to lead screws. This precision is crucial in industries like automation and robotics. The backlash in ball screws is often less than that in lead screws. However, they can be more expensive and may require more maintenance. These factors should be evaluated carefully based on your application needs.

Choosing the right ball screw involves considering factors like load capacity and speed. It’s essential to review specifications and compatibility. Mistakes in choosing the wrong type can lead to inefficiencies. Keeping a close eye on your project requirements will ensure better performance and longevity.