What are the Benefits of Silicone Rubber Buttons?

In the world of manufacturing, the importance of Silicone Rubber Buttons cannot be overstated. Renowned expert Dr. Emily Carter states, “Silicone rubber buttons blend durability with user-friendly design.” This blend of qualities makes these buttons essential in various industries. They provide an excellent solution for products requiring reliable and responsive controls.

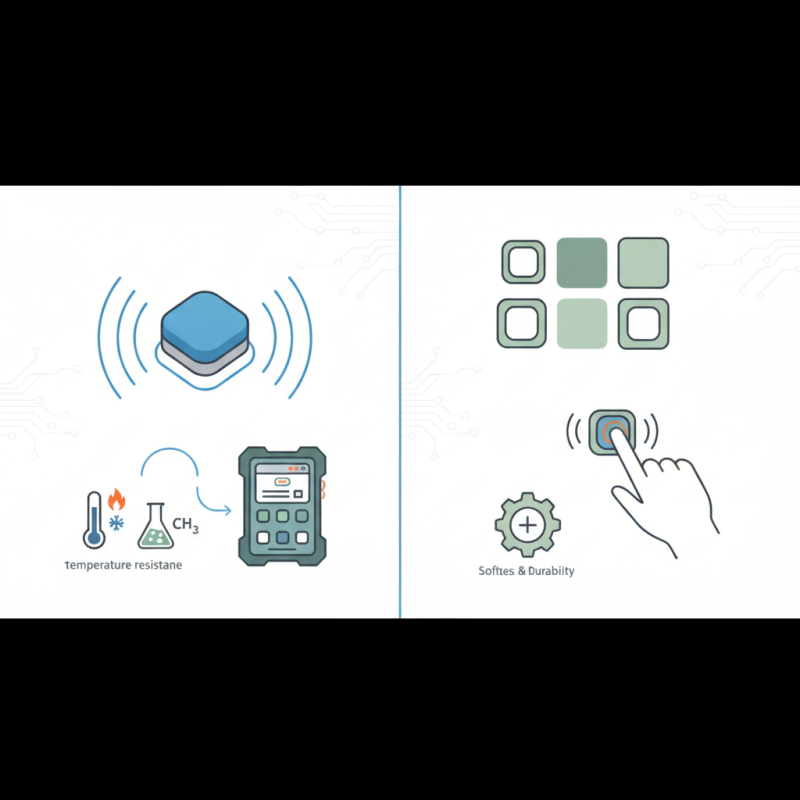

One significant benefit of silicone rubber buttons is their resistance to harsh environments. They can withstand a wide range of temperatures. This feature is crucial for devices used in extreme conditions. Furthermore, their flexibility allows for various shapes and sizes, catering to specific product designs. Yet, achieving perfect consistency in production can sometimes pose challenges.

The tactile feedback offered by silicone rubber buttons enhances user experience. Many users appreciate the soft, cushioned feel. However, ensuring the right amount of resistance requires careful calibration. Manufacturers must balance softness and durability. This ongoing pursuit of perfection is key to maximizing the potential of silicone rubber buttons.

Benefits of Silicone Rubber Buttons in Various Applications

Silicone rubber buttons are gaining popularity across various industries. Their flexibility and durability make them ideal for many applications. In medical devices, they offer a reliable tactile response. Users appreciate the softness of the buttons. This feature enhances user experience. It is crucial in sensitive environments where precision matters.

In consumer electronics, silicone buttons are lightweight and water-resistant. They can withstand multiple presses without wear. This longevity saves costs in the long run. However, some might overlook how they can trap dirt over time. Regular cleaning is needed to maintain their appearance and function. This aspect can be a drawback for manufacturers and users alike.

These buttons find their way into automotive controls too. Their ability to endure extreme temperatures is beneficial. Still, they may feel too soft for some users. Finding the right balance between softness and firmness is essential. Companies must consider feedback from users. Overall, silicone rubber buttons have transformative potential in diverse applications. However, continuous improvement is necessary to address specific user needs.

Durability and Longevity of Silicone Rubber Buttons

Silicone rubber buttons are known for their durability and longevity. They can withstand extreme temperatures, making them ideal for various environments. Heat, cold, or moisture do not easily damage them. In fact, these buttons maintain their shape and function even after prolonged use. This quality makes them suitable for devices that often face harsh conditions.

However, not all silicone buttons are created equal. Some may show wear and tear faster than expected. The effectiveness of the silicone can diminish after countless presses. It’s essential to choose the right formulation for specific applications. Regular maintenance can help identify issues before they become major problems. Users may overlook subtle signs of degradation, which can lead to device malfunctions.

Moreover, the aesthetic appeal of silicone buttons cannot be ignored. They can be molded into various shapes and colors. This flexibility allows designers to create intuitive interfaces. Still, this creativity must be balanced with practicality. Too much customization may affect the reliability of the buttons. Users must consider functionality as a priority, even when tempted by design innovations.

Enhanced User Experience with Silicone Rubber Buttons

Silicone rubber buttons enhance user experience in many ways. They provide a soft, tactile feel that users appreciate. When pressed, these buttons respond with a satisfying click. This feedback makes interaction enjoyable. Unlike hard plastic, silicone can absorb shock. It feels comfortable, especially during extended use.

The surface of silicone buttons can be customized. This means colors and shapes can vary widely. Users enjoy unique designs that match their style. They also offer a non-slip grip, making them easier to use. Many people with mobility issues find silicone buttons easier to press.

However, there are challenges. Over time, silicone may lose its shape. This can affect usability. Cleaning these buttons can also be tricky. Dirt may accumulate in crevices, impacting performance. Users should consider these factors before making a choice. The balance between aesthetics and functionality is important.

Customization Options for Silicone Rubber Buttons

Silicone rubber buttons offer extensive customization options, making them a popular choice in various applications. Companies can choose different colors, shapes, and sizes to match their product designs. This flexibility allows for unique branding opportunities. For instance, a vibrant button can draw attention while a more subtle one can blend in elegantly. However, it's important to avoid colors that clash with other design elements.

Texture also plays a role in customization. Smooth surfaces provide a sleek look, while textured buttons can enhance grip. The feeling of a button can greatly affect user experience. Yet, finding the right balance is crucial; too much texture may distract users. Less often, designs can be overly complicated, making production harder and increasing costs. Simplicity often leads to more functional designs.

Moreover, the option for printing or engraving logos adds another layer of personalization. But, businesses should be cautious. Overly intricate designs may fade or wear off over time. Consideration of durability is essential. Customers appreciate well-made buttons that stand the test of time. Customization can enhance appearance, but it shouldn't compromise quality and usability.

Environmental Impact and Sustainability of Silicone Rubber Buttons

Silicone rubber buttons are increasingly popular due to their durability and design versatility. But what about the environmental impact? Silicone is not biodegradable. This raises concerns about long-term waste. Many consumers appreciate its longevity, yet this very quality can contribute to environmental issues.

Production of silicone rubber involves significant energy use. Factories emit greenhouse gases, which is concerning. However, silicone can be recycled. Recycled silicone can be used to create new products, reducing overall waste. Still, this process is not widely implemented. Many silicone items end up in landfills, where they persist for hundreds of years.

Sustainability is a complex issue. The materials used in silicone rubber buttons can sometimes be sourced from fossil fuels. This reliance on non-renewable resources is a significant drawback. There’s a growing need for innovation in eco-friendly alternatives. As consumers, we should question our choices and seek out more sustainable options. With the right changes, silicone can become a more responsible choice.

Benefits of Silicone Rubber Buttons

This chart illustrates the various benefits of silicone rubber buttons, highlighting their durability, water resistance, temperature resistance, eco-friendliness, and customization options, each represented by their respective percentages. Silicone rubber buttons are a sustainable choice with multiple advantages, making them a favored option across numerous applications.