How to Choose the Right Laser Cutting Machine for Your Needs?

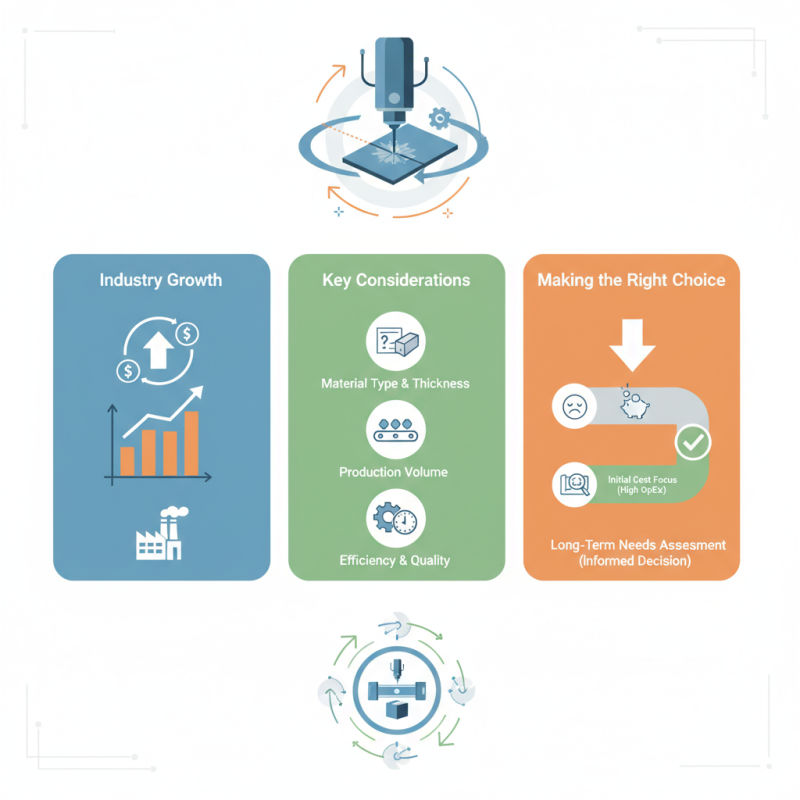

Choosing the right laser cutting machine can be challenging. The industry has seen significant growth, with projections indicating a market value of over $6 billion by 2025. However, understanding specific needs is crucial. As expert John Smith states, “Selecting the right laser cutting machine directly impacts efficiency and product quality.”

Each laser cutting machine offers unique features. Factors like material type, thickness, and production volume matter. For example, some machines excel in cutting metals, while others handle wood better. Often, businesses rush the decision. They overlook the importance of aligning technology with production goals.

Some machines may seem appealing based on initial cost. Yet, they can lead to higher operational expenses later. Understanding long-term needs is essential. Companies should carefully evaluate their requirements. Only then can they make an informed choice about the right laser cutting machine.

Understanding Your Material Requirements for Laser Cutting

When choosing a laser cutting machine, understanding your material is crucial. Different materials react differently to laser cutting. For instance, plastics require specific wavelengths for optimal results. Carbon steel may demand a high-powered machine, while acrylic often works well with lower wattages. Industry data shows that about 60% of projects fail due to improper material choice.

Material thickness plays a key role too. A report from a leading manufacturing group highlights that machines with a 100-watt laser can cut metal up to 1/4 inch thick efficiently. However, cutting thicker materials may need a more powerful unit. Experimenting with material samples can be a frustrating but necessary process.

Moreover, the type of finish you desire impacts material selection. Some materials burn easily, leading to unsatisfactory edges. In contrast, others may produce clean cuts but may warp under heat. Balancing these factors requires careful consideration and possibly trial and error. Finding the right harmony can lead to successful projects, but perfection often demands patience and iteration.

Identifying the Right Laser Cutting Technology for Your Application

Choosing the right laser cutting technology is crucial for your application. The primary types include CO2 lasers, fiber lasers, and solid-state lasers. CO2 lasers excel in cutting non-metal materials. They work well with wood, acrylic, and fabric. Fiber lasers, meanwhile, shine when dealing with metals like steel and aluminum. According to an industry report, fiber lasers provide an energy efficiency of about 30% higher than CO2 systems. This efficiency can lead to significant cost savings.

When selecting a laser cutting machine, consider the thickness of the materials you will process. For instance, CO2 lasers handle materials up to 25mm thick, while fiber lasers can cut steel up to 20mm thick. Evaluating the material types you frequently use can help in making a more informed decision. Look also for machines with adjustable settings for versatility.

Tips: Always assess the software integration of the machine. Ease of use can vary significantly between models. Regular maintenance also plays a vital role in machine longevity and performance. Keep in mind that your choice may need reevaluation as your business evolves. New technologies arise regularly, making it essential to stay updated on advancements.

Assessing the Power and Speed Needs of Your Projects

When choosing a laser cutting machine, understanding power and speed is crucial. The power affects how thick or dense materials can be cut. For example, a higher wattage laser can easily cut through metals, while a lower wattage is suited for thinner woods or acrylics. This directly influences project outcomes. If you need precision in delicate materials, a lower power might be ideal. However, a strong machine can overwhelm softer substances, resulting in burn marks or damage.

Speed also plays a significant role in the overall efficiency of your project. A faster cutting speed can boost productivity but may compromise accuracy. Balancing speed and precision is key. You might find that accelerating too quickly leads to a rough edge. Conversely, operating too slowly can waste time and resources. Testing different settings can help discover optimal performance. Don't overlook the importance of material type and thickness as they will guide your choices on power and speed. Ultimately, experimenting with various settings reveals what works best for your specific applications.

Assessing Power and Speed Needs of Laser Cutting Machines

Evaluating Budget Considerations and Total Cost of Ownership

When evaluating budget considerations for a laser cutting machine, start by assessing initial costs. The purchase price varies widely. Many machines fall within a range of a few thousand to tens of thousands. Your specific needs will dictate whether a lower-cost option is sufficient or if you require advanced features.

But initial costs are just part of the total cost of ownership. Consider operational expenses like electricity and maintenance. Ask yourself: How often will you use the machine? Increased usage can lead to higher power bills. Additionally, routine maintenance can accumulate costs over time. A low initial price may be tempting, but hidden costs can add up.

Don’t forget about software and training expenses. You'll need suitable software for design and cutting. Training for staff can be overlooked but is essential for efficiency. Are your team members comfortable with new technology? Reflect on these aspects. Ultimately, a thorough evaluation will lead to better financial decisions.

How to Choose the Right Laser Cutting Machine for Your Needs?

| Machine Type | Initial Cost ($) | Operating Cost per Hour ($) | Material Compatibility | Maintenance Frequency (Months) | Total Cost of Ownership (5 Years) ($) |

|---|---|---|---|---|---|

| CO2 Laser Cutter | 8,000 | 20 | Acrylic, Wood, Leather | 12 | 10,000 |

| Fiber Laser Cutter | 15,000 | 25 | Metal, Plastics | 10 | 20,000 |

| YAG Laser Cutter | 12,000 | 30 | Metal, Ceramics | 8 | 18,000 |

| Crystal Laser Cutter | 25,000 | 40 | Glass, Plastics | 15 | 45,000 |

Researching Manufacturer Support and Machine Reliability

When choosing a laser cutting machine, manufacturer support is crucial. This aspect can significantly influence your machine's performance over time. Look for suppliers that offer robust customer service. Quick response times can save you from long downtimes. Ask about their support hours. Are they available on weekends or holidays? This flexibility can be a game-changer when urgent issues arise.

Reliability is another essential factor. Examine the machine’s build quality. A sturdy design often correlates with longevity. Investigate user reviews and feedback. Sometimes, what looks good on paper may not perform well in the real world. Don’t hesitate to contact existing users. Their insights can reveal issues you might not anticipate. You must weigh the potential risks against your production needs. Sometimes, the perfect machine may not be perfect for you. Reflecting on these factors can guide you to a more informed decision.